First in a series

ARLINGTON – Brian Lade, president of Smokey Point Productions, grew his first marijuana plants clandestinely in the family garage when he was 17. Through his ventures over the years in the marijuana trade – selling to medical dispensaries and underground – today he is enjoying the sweet smell of success for a passion that became legal in Washington in 2012.

Smokey Point Productions creates and sells cloned plants, and sells flower and concentrates to marijuana stores statewide.

SPP’s parent company, The Clone Zone, sold 1,000 clones on Craigslist in 2011 and made $1,000 in a single week, then stayed sold out supplying all the other farmers with plants for its entire history. With those types of returns and an opportunity to turn legitimate with the legalization of recreational marijuana, his company has blossomed.

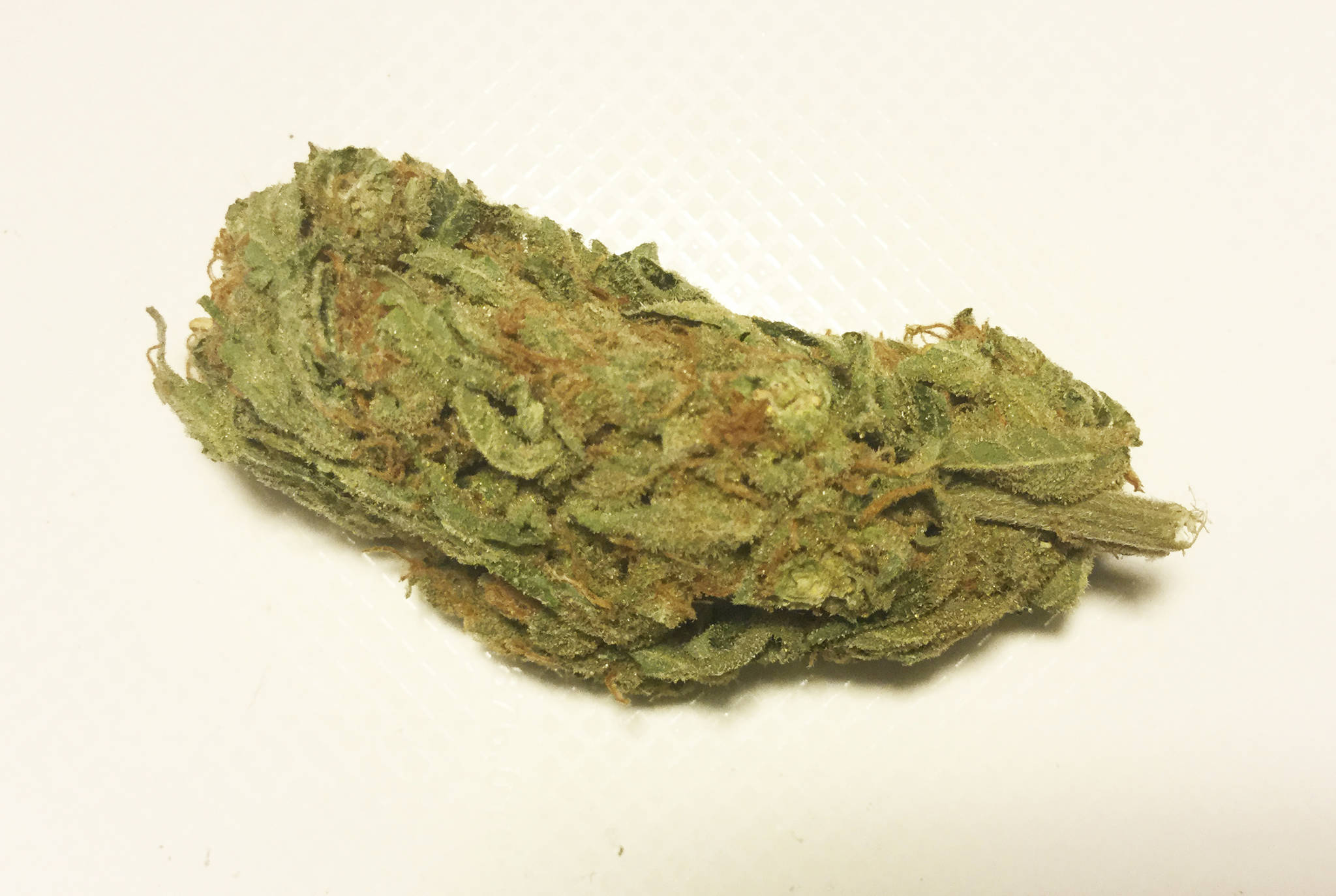

Today, his 135,000 square feet of warehouse space in Arlington is turning out 1,700 pounds of buds monthly from scores of custom-bred strains like Dirty Girl, Lodi Dodi and Cinderalla’s Dream, up from 100 pounds when he started. Lade can also process more than 2,000 pounds of purchased marijuana into cannabis oil and other concentrates for vaping.

“It’s a completely professional business,” Lade said. “A lot of people are going to think that we’re pot-smoking hippies sitting around singing Kumbaya and strumming an acoustic guitar. “We’re the farthest thing from that.”

You don’t have to tell that to the city of Arlington.

With local voters favoring legalization, and the city poised for economic development looking at an emerging new industry that could help fill that niche and empty warehouses, Arlington – with not much data to guide it – took a risk every bit as big as the one that growers took as startups.

“The Bayliner redevelopment and the passage of I-502 and us getting our codes and ordinances written were a nice alignment of the stars,” Arlington Mayor Barb Tolbert said.

The mainstreaming of marijuana is big business in Arlington, creating jobs and revenue while becoming good corporate partners with the community to address pressing social issues and lending a hand through volunteer projects.

Arlington counts 14 producers inside the city limits, and 30 overall with an Arlington address, ranging from intimate mom and pop farm growers to industry leaders such as Smokey Point Productions on 67th Avenue NE.

Combined, Arlington-area producers currently employ about 800 people, a number that they expect to increase to 1,200 within 3-5 years based on industry growth projections.

The larger operations run out of nondescript buildings with signage no larger than what fits on a door, and often blend into industrial parks. Some are located in the Arlington Advanced Manufacturing Park, formerly Bayliner, near Arlington Airport, operating alongside a variety of other manufacturers inside a gated industrial community.

Smokey Point Productions has grown from a family run business to just under 100 uniformed employees. Lade’s goal is to expand to 134 employees when he builds his second 75,000-square-foot building, which was the same number of employees who worked at the facility before the previous owners closed down.

Lade has designed innovative growing facilities that have enabled the company to increase its production scale while still hand-watering, hand-trimming and hand-weighing all buds to maintain high quality. “We give each one of our plants a lot of individual attention and care,” he said.

He achieves the same controlled environments in each of 10 “bloom rooms,” with one room harvested each week, resulting in efficient process management and reduced operating expenses, while yielding a large quantity of high-quality product.

A machine mixes soil ingredients, pours the dirt into containers and then digs holes for young plants. A conveyor belt carries the container to an employee who does the delicate job of planting. Lade’s also proud of his compost tea brew, a 500-gallon vat that pumps “liquid gold” to all his rooms, an all-natural alternative to pesticides.

Lade is a neat freak for the good of his business, employees and customers. He demands a clean, sealed environment to keeps pests, pathogens and contaminants out, maintaining consistent air quality using hospital lab grade filters. He personally does the laundry each day, washing uniforms and other work clothes.

The company breeds and clones in-house, producing popular genetic strains that are available on store shelves with retailers it supplies. SPP also produces extracts, vaping and dab products, and concentrates for users who prefer not to smoke. He also has a dedicated edibles kitchen and master baker who is testing goodies for a future line of truffles, taffies, caramels and gummies.

For shipping, SPP created two custom-packaging and bar-coding machines linked to the company’s inventory management system to comply with state regulations, a time-saving operation unique to his company, Lade said.

The operation serves as an example that marijuana is a sophisticated manufacturing process on par with other skills-based traditional industries.

Lade is quick to praise Arlington leaders for believing in his dream. “They went for it. They invested in us – in me – when other people wouldn’t,” he said.

“I’m proud of where we’re at and I think the ‘Smokey’ plays well to the cannabis industry, I’m barbecuing bud up here in the Smokey Point area,” Lade joke. The area tooks its name from a well-known barbecue joint, the Smokey Point Cafe, that opened in 1946.

SPP/The Clone Zone’s total sales are $8.2 million, with year-to-date sales of $2.5 million, among the top three producers in Snohomish County. The company is the major supplier to Main Street Marijuana in Vancouver, Wash., the state’s busiest marijuana retailer, Kushmart in Everett the past seven years and other retailers statewide.

Arlington’s two retailers allotted by the Liquor and Cannabis Control Board in Arlington, Cascade Kropz and PRC, are generating more than $1 million a month in sales, according to the 502data website.

Marysville opted to keep the marijuana business out of the city, and that has driven customers to the Arlington shops, adding to its tax base.

In 2016, Arlington collected $87,298 in marijuana excise tax revenue, with $27,498 received for the first two quarterly distributions in 2017. City finance director Kristin Garcia said that less is expected for 2017 due to recent legislative changes that reduced the cap from $15 million to $6 million apportioned out to cities.

In the fledgling years of legalization, marijuana producers are disappointed that the state keeps virtually all of sales tax generated, while only funneling a smidgen back to the communities that took a chance on the industry and should benefit more from that decision.

The industry has also been beneficial for other local businesses and contractors.

For example, Arlington RV & Welding Supplies completed a $300,000 contract with SPP to create 850 metal portable growing plant tables.

“I worked with as many local businesses as possible to get my campus built,” Lade said.

Citing other companies, Cascade Door and Hardware took care of all the doors and Penway Printing does their media, artwork and advertising.

Marijuana producers also have spent time seeking ways that they can help the community by being good corporate stewards. That has impressed the mayor and other city leaders. The Arlington Cannabis Coalition formed over a year ago as a “loose affiliation” of leaders from all the cannabis companies in the Arlington area. Pioneer Nuggets – as well as SPP – is one of those companies that meets monthly, sometimes inviting the mayor and other local leaders.

Fitz Couhig is CEO of Pioneer Nuggets, a Tier 2 marijuana producer with 6,000 square feet of grow space in the Arlington Advanced Manufacturing Park and pumping out about 120 pounds of bud per month, up from 10 pounds, with 24 employees on the payroll.

“Everybody has been really busy starting their companies,” Couhig said, but as they have become more established, they have been more open about the kind of collective perception they are giving off to the community.

“The way it works is just to give back to the community that has opened its doors to us, while we work together on industry standards that we can push forward because we’re a cohesive unit that is in one area,” said Couhig, who is a busy Arlington Rotary Club member. In other words, “What can we do to improve the industry while we make sure that we’re working together to be a positive part of the community.”

So far, coalition members have participated in work parties at Twin Rivers Park and other parks, and supported activities through Arlington Runners Club events, kickball and full-size foosball tournaments to raise thousands of dollars for the city’s new Social Services Fund, or as the mayor refers to it, the Opioids Flex Fund.

Concerned coalition members approached the city eager to help them to combat the opioid epidemic in Arlington – whatever it takes.

“The cannabis companies are perfectly positioned to be able to help, and a town of this size, I think it’s possible to really make a change, and we could be a shining example for the state and the nation,” Lade said.